Natural talent cork

Cork is a small wonder of nature. It comes with fabulous properties and

and

makes us marvel at the variety of ways it can be processed.

About cork

The name cork is usually used to describe the outer bark of the cork oak (Quercus suber L.), which reaches several centimetres in thickness over time. This bark is a plant tissue that is formed from dead microcells with the help of phellogens. In a certain amount of time, a certain amount of thickness is formed through the accumulation of suberin, a biopolymer that is impermeable to water, waterproof and elastic. Inside the cells there is air, but no carbon dioxide. Other main components of the natural material are composed of linguin (has an insulating effect), tanins, polysaccarides and waxes. This natural composition gives cork its unique properties and remains unmatched to this day.

Cork was already used as a material in antiquity. Cork was first used as the sole of sandals - also on the feet of Roman soldiers on their way halfway around the world. Whether the cellar master of Dom Perignon discovered cork as an ideal material for bottle closures is uncertain - today, however, cork is the raw material for a multitude of applications.

The cork oak

(Quercus suber L.) is an evergreen hard-leaved plant. It grows ten to twelve metres high with a trunk diameter of up to one metre. A cork oak can only be peeled for the first time at the age of 20 years. This produces the so-called "virgin cork", which is mainly used for decorative purposes. The bark then grows back within nine to eleven years. In the process, the quality of the cork improves, it becomes finer-cell and smoother and can thus also be used industrially.

Cork oaks reach an age of up to 350 years - 150 years it is peeled. An average tree yields several hundred kilos of cork per harvest and this for many generations. The cork harvest is done in a sustainable way without damaging the tree.

Cork oak forests cover a cultivated area of about 2.5 million hectares in the countries: Portugal, Spain, Algeria, Morocco, France, Italy and Tunisia.

Cork production is secured by annual replanting. No tree may be felled or transplanted without state permission.

More than half of the world's annual production is harvested in Portugal. Here, special care has always been taken with this raw material. The first laws to protect cork oaks date back to the fourteenth century.

With increasing environmental awareness, the cork oak is becoming more and more interesting. It is the only tree whose bark can be extracted without causing injury and which grows back on its own. Cork is indeed a renewable, environmentally friendly raw material. Moreover, the cork oak has another remarkable property in that the peeled tree binds five times more carbon dioxide than the unpeeled tree. These unique properties make cork a natural and sustainable product whose use helps to preserve a unique habitat.

Environmental impact

Cork oak forests are perfectly adapted to the semi-arid regions of southern Europe, prevent desertification and form a perfect habitat for many rare animal and plant species.

The economic use and protection of the cork oak forests are important for biodiversity, prevent desertification and promote regional social balance.

Cork can also make an important contribution to protecting against global warming. The bark of the cork oak regenerates itself after harvesting and it is known that a harvested cork tree binds three to five times more carbon dioxide than an unharvested one. Portuguese cork oak forests alone absorb 4.8 million tonnes of CO² per year, and the entire cork oak forests of the Mediterranean region absorb 14 million tonnes of CO².

The cork industry itself is very "eco-efficient". All cork is used, not a gram is wasted. Even cork dust is still used to generate energy. By buying and using cork products, you support the preservation and expansion of the cork oak forests, you support workers and craftsmen and, above all, you get to enjoy the natural talent that is cork! You too can support the natural product cork!

Properties

The bark of the cork oak has a unique honeycomb structure consisting of small cells filled with air. This structure creates flexibility and stability. In addition, each cell is encased in a waterproof and airtight membrane. About 30-40 million of these cells are contained in one cubic centimetre of cork, i.e. about 85%-90% of cork is made of air, resulting in a very low density of about 0.12-0.20/cm³.

Due to this structure, cork has some remarkable and useful properties:

- Due to its low density, cork floats very well. This is why cork has been used as a float in fishing for centuries.

- Its elasticity and impermeability allow cork to be used as bottle caps and seals. Cork is impervious to liquids and gases.

- Ein niedriger Wärmeleitwert macht Kork zu einem der besten natürlichen Dämmstoffe

- Kork ist im Temperaturbereich -200 bis +120 verwendbar, verhält sich feuerhemmend und setzt bei der Vebrennung keine toxischen Gase frei

Applications

What do Roman sandals and the space shuttle have in common? Well, in both "products" cork provides very specific properties: once as footfall insulation, once as heat protection. In fact, cork naturally brings with it numerous properties that make it an all-round talent for a wide range of applications and uses. Cork can be moulded to perform almost any task. In any shape and size, cork offers customised solutions (discs, blocks, sheets, rolls, granules).

Some of the possibilities are briefly outlined below: in masonry brick construction, in timber frame construction, in brick and timber construction walls, in wet or dry floor superstructures, for on-roof and inter-rafter insulation.

- as thermal composite systems

- as natural impact sound and thermal insulation, for example under parquet, laminate, textile floor coverings, PVC, etc.

- as natural thermal insulation on walls and ceilings, for example as underlay wallpaper

- for vibration and sound insulation

- for information boards and pin boards

- As granulate (also called cork shot) in dry construction for filling in stud walls and for insulation between rafters in wooden beam ceilings.

- in fashion and clothing

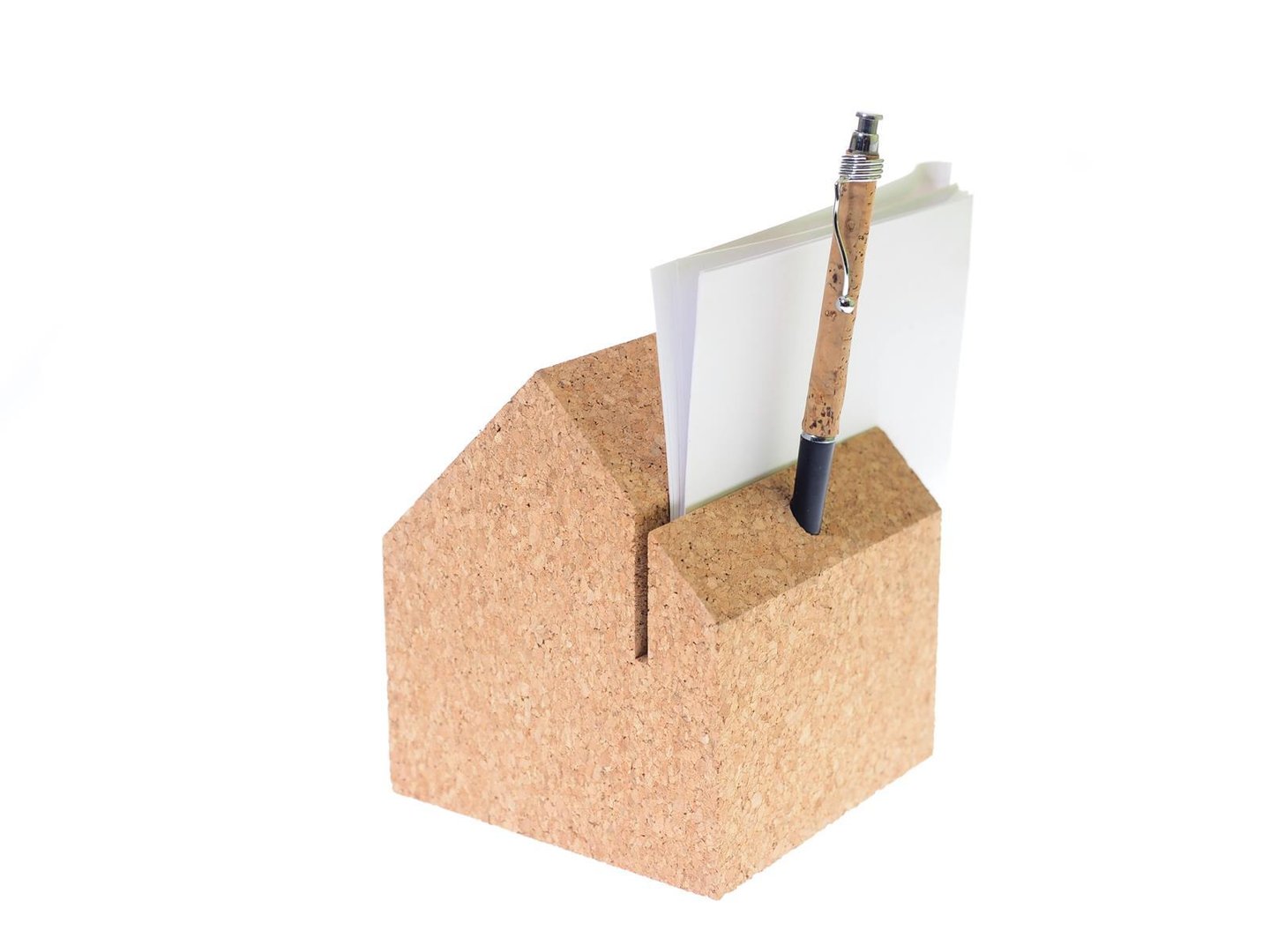

- as accessories

- as a briefcase, timer, etc.

- as well as gifts in the broadest sense.

Heat shield of the Ariane rocket

Serpentine Pavilion London 2012

Chalet in Pena/Sintra

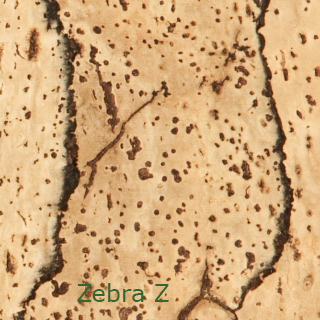

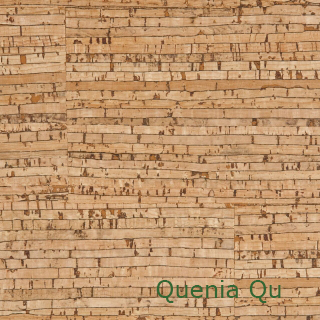

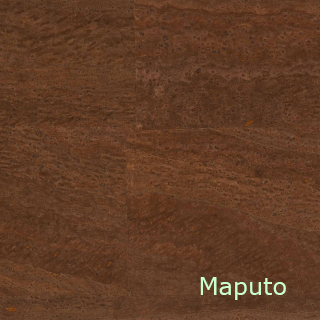

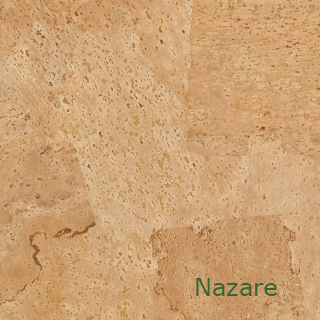

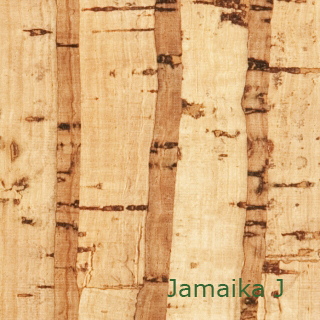

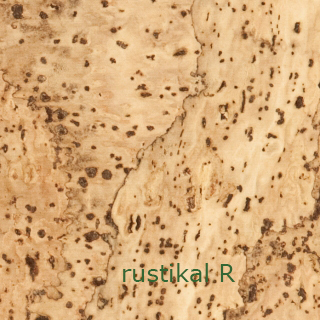

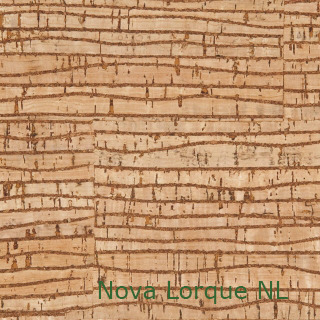

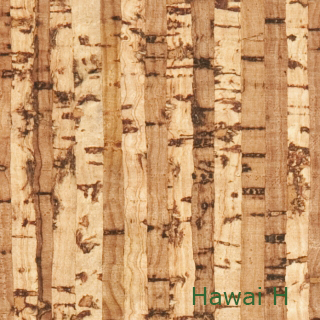

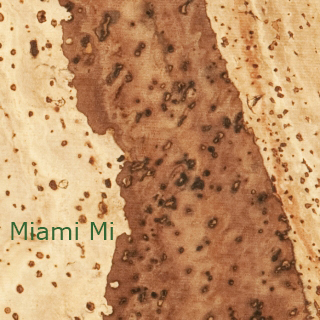

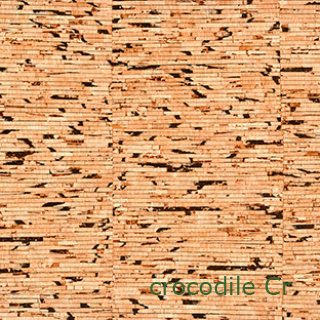

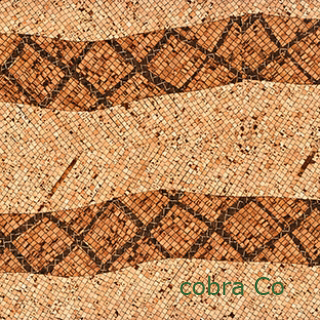

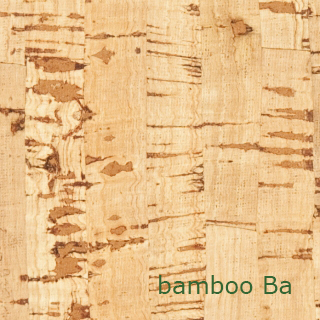

Structures of cork fabric

Cork fabrics or also called cork leather, in their great variety with their names you can see here.

Cork fabrics available at korkie.de